The problem is the fact lawmakers and the public have exhibited a stunning insufficient consciousness in the challenges, Gomes suggests. “If for some motive the many energy Employed in the United States, say, was created in China, the American folks wouldn’t enable it,” he states.

Using this method, scientific analysis in the API can start out promptly, which is crucial for both drug builders and clients who look for thriving cure. As This system improvements towards validation and commercial start, greater emphasis is placed on improving upon produce and getting higher system comprehending to support system validation and eventual start.

Van Kley (Cambrex): When acquiring an API manufacturing system, There are a selection of crucial criteria from a simple and logistical standpoint. Firstly, can the chemistry be executed for the manufacturing web-site in terms of managing the required solvents and reagents, and does the plant hold the capabilities to support the temperature ranges of the method?

Stolle and Poechlauer (Patheon): Our key issues in optimizing system chemistry are driven by optimizing the support to our purchasers. This approach comprises issues including:

The effect of CGMP violations depends on the character of These violations and on the precise medicines involved. A drug made in violation of CGMP should still fulfill its labeled specs, and the chance that the drug is unsafe or ineffective might be minimum. Thus, FDA’s suggestions will be unique to the situation, and health and fitness care specialists are ideal able to equilibrium dangers and Positive aspects and make the appropriate decision for his or her people.

The CordenPharma Peptides technology platform delivers specialised abilities across a number of cGMP amenities within our built-in community, from early phase to industrial provide of Superior peptide APIs.

Precision is even more difficult In relation to counting raw materials for medications, but marketplace watchers concur that the volume coming from Asia has skyrocketed. The EFCG estimates that upward of 80% of chemical compounds accustomed to make drugs offered in Europe now originate from China and India.

The provider should be re-audited in a specified frequency to validate ongoing effectiveness. A rationale for your minimum audit frequencies for each supplier ought to be documented. The common market exercise is every single three–five many years for non-GMP-regulated crucial Uncooked materials.

“I’ve presented it many imagined, And that i in fact think it might be pretty a robust provide chain,” Dude Villax, CEO of Hovione, told C&EN in late March.

These USP paperwork tend not to apply to important Uncooked materials for instance cleansing and germicidal agents Employed in drug manufacturing amenities due to the fact these sorts of items are meant to clean and disinfect surfaces. Some surfaces on which these cleansing brokers are utilized can also be in direct connection with drug products; nonetheless, residues are usually eliminated ahead of the machines is made use of.

Consequently, pharmaceutical manufacturers are demanding good quality technique compliance with sufficient benchmarks and elevated data transparency from their suppliers.23 Some raw product suppliers require far more provenance data from their suppliers, for instance resource, origin, and other critical information for traceability needs.

iv. Excellent Method Record (Sec. 820.186) 189. Various remarks mentioned that the regulation need to more intently harmonize with ISO 9001:1994. A few responses mentioned that the regulation really should involve the requirements for a high quality manual. A person comment said that typical good quality system processes and directions should not be necessary in the DMR because the DMR is machine particular, and plenty of excellent procedure techniques are usually not tied to a particular device.

187. Just one comment on Sec. 820.184 stated that labeling really should not be essential within the DHR mainly because it is previously expected in the DMR. Yet another comment said that some products have twenty five or even more labels and that only the principal identification labels are important during the DHR. 1 comment stated the need should be amended because it explicitly demands that dates and portions for every batch be from the DHR, when only implying from the normal requirement which the DHR will have to also comprise the batch check info. FDA agrees that it might not be essential to involve all labeling Employed in the DHR. However, FDA continues to think, as it stated from the preamble to proposed regulation revealed check here inside the Federal Sign up on November 23, 1993 (58 FR 61952 at 61968), that increased Command in excess of labeling is necessary due to the lots of labeling glitches resulting in recollects. As a result, FDA has retained a need relevant to labeling within the DHR, but revised it to really make it significantly less burdensome. The need was amended to ``the principal identification label and labeling'' which is in keeping with that contained in the original CGMP regulation, Sec.

These are generally substances that encourage the split-up or disintegration of tablets or capsules while in the digestive tract to help you your body absorb the medication.

Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Danica McKellar Then & Now!

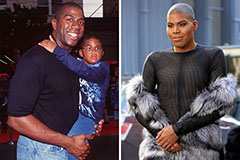

Danica McKellar Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now!